JAMA Netw Open 2(8):e199144.Hazard Analysis and Critical Control Points (HACCP)įood hygiene laws state that all business should have a documented HACCP system in place. Warren CM et al (2019) Prevalence and severity of sesame allergy in the United States. Palma A (1985) Mashed potatoes and Bacillus cereus poisoning. Mortimore S, Wallace C (2013) HACCP: a practical approach. King H, Michaels B (2019) The need for a glove-use management system in retail foodservice. In: Food allergens best practices for assessing, managing, and communicating risks. King H, Bedale W (2018) Managing food allergens in retail quick-service restaurants. King H, Bedale W (2017) Hazard analysis and risk-based preventive controls: improving food safety in human food manufacturing for food businesses. King H, Ades G (2015) Hazard Analysis and Risk-Based Preventive Controls (HARPC): the new GMP for food manufacturing. King H (2013) Food safety management: implementing a food safety program in a food retail business.

Jorgensen H et al (2005) An outbreak of staphylococcal food poisoning caused by enterotoxin H in mashed potato made with raw milk. Department of Health and Human Services, Public Health Service, Washington, DC. įood and Drug Administration (FDA) (2017) FDA food code. Department of Health and Human Services, Public Health Service.

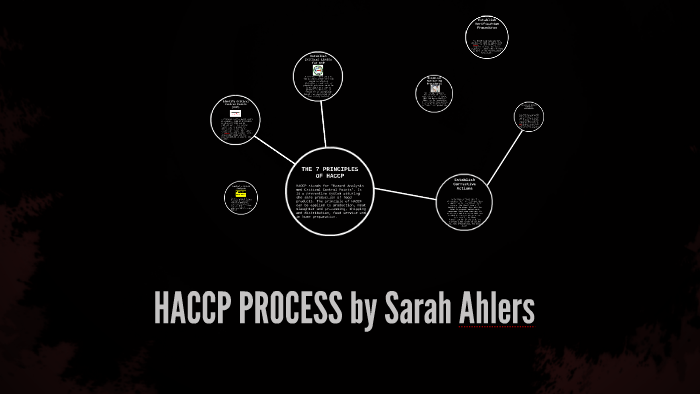

HACCP PROCESS 3 COMPLEX FOOD PREP MANUAL

Morb Mortal Wkly Rep 49(10):207–211įood and Drug Administration (FDA) (2006) Managing food safety: a manual for the voluntary use of HACCP principles for operators of food service and retail establishments. Ĭhandler B et al (2000) Outbreaks of Norwalk-like viral gastroenteritis – Alaska and Wisconsin, 1999. Content source: Centers for Disease Control and Prevention, National Center for Emerging and Zoonotic Infectious Diseases (NCEZID), Division of Foodborne, Waterborne, and Environmental Diseases (DFWED). Dairy Food Environ Sanit 15(7):420–422ĬDC (2010) Multiple- serotype Salmonella gastroenteritis outbreak after a reception, Connecticut, 2009. The actual management of the hazards in foodservice operations via the monitoring, corrective actions, verifications, documentation, and validation functions of the FSMS can enable the foodservice business to establish Active Managerial Control of the risk factors that lead to most foodborne illnesses, injury (i.e., physical contaminants), and disease outbreaks.īrent J et al (1995) Botulism from potato salad. The Food Safety Management Systems (FSMS) are then developed based on this Process HACCP plan and the Prerequisite Control Program and then used by a Certified Food Protection Manager (CFPM) to monitor the controls during food preparation and other restaurant processes in the Prerequisite Control Program (described in detail in Chap. This is required in order to determine the most effective controls (CCPs and PCPs) for each of these hazards to prevent foodborne illnesses and outbreaks. The process approach to HACCP (called Process HACCP) recommended by the FDA is used to identify the hazards that occur during the food preparation processes of a complete menu and during actions made in the Prerequisite Control Program (e.g., employee personal hygiene, source of food ingredients, effective cleaning and sanitation SOPs, etc.). This does not mean that ensuring foods are cooked, cooled, and held at the right temperatures is not preventive, but that it is not comprehensive to control all the hazards, and thus all the food safety risk in a foodservice establishment. In fact, there are more foodborne illnesses caused by employees working sick than those caused by uncooked or improperly held foods. Checking temperatures using paper checklist as the primary means to prevent foodborne illnesses and disease outbreaks does not prevent all known foodborne illness risk.

0 kommentar(er)

0 kommentar(er)